Nylon vs Polyester Drawstring Bag: A Practical Comparison

TL;DR

Choosing between a nylon and polyester drawstring bag depends on your priorities. Nylon is generally stronger, more durable, and has a superior strength-to-weight ratio, making it ideal for heavy-duty use. Polyester is more budget-friendly, repels water naturally, and offers better resistance to UV rays and abrasion, which helps it maintain its color and appearance over time.

Durability and Strength Showdown

When selecting a drawstring bag, durability is often a primary concern. The material's ability to withstand daily wear, resist tearing, and handle heavy loads determines its lifespan and reliability. Both nylon and polyester are synthetic fabrics known for their strength, but they exhibit different performance characteristics under stress. Understanding these nuances is key to choosing the right bag for demanding activities versus everyday use.

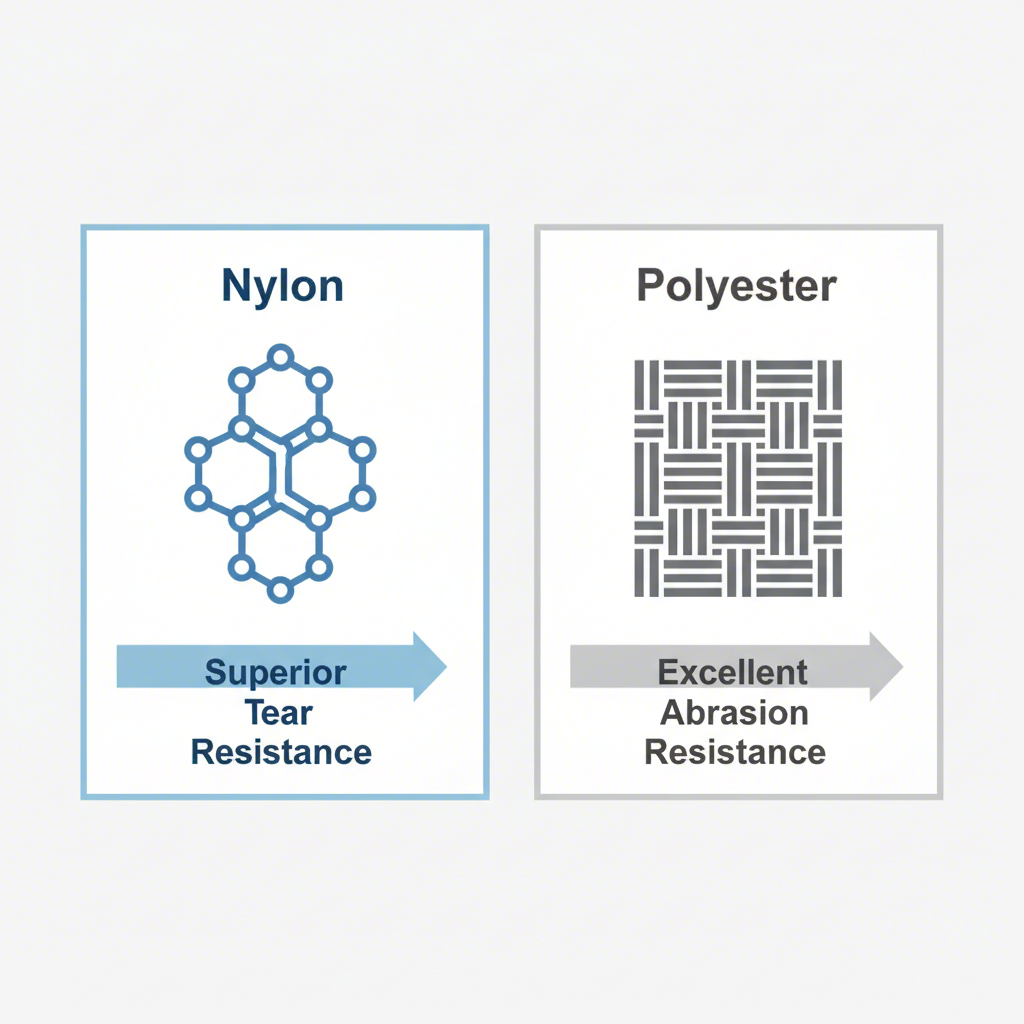

Nylon, a polyamide, is renowned for its exceptional tensile strength and elasticity. As detailed by Yanxin Bag, its molecular structure gives it impressive resistance to tearing and abrasion, making it the preferred material for items that endure significant strain, like hiking backpacks or travel gear. This is why high-performance tactical bags often use robust fabrics like 1000D Cordura nylon, which is built to handle extreme conditions. Nylon’s strength-to-weight ratio is also superior, meaning it can offer more strength without adding extra bulk.

Polyester, while also a strong material, doesn't quite match nylon's raw strength. However, it excels in other areas of durability. According to Tortuga Backpacks, polyester is more resistant to abrasion and pilling. This means a polyester bag is less likely to develop a fuzzy, worn-out look over time, helping it appear newer for longer. For everyday items like school backpacks or promotional tote bags, a common material is 600D polyester, which provides a great balance of resilience and lightweight construction for less intensive use.

Ultimately, the choice comes down to the intended application. For carrying heavy gear or for use in rugged environments, nylon's superior tear resistance makes it the more dependable option. For daily use, where the bag might rub against surfaces but won't carry extreme weight, polyester's abrasion resistance and ability to maintain its appearance offer a practical advantage.

| Feature | Nylon | Polyester |

|---|---|---|

| Tensile Strength | Higher (more resistant to tearing) | Lower |

| Abrasion Resistance | Good | Excellent (resists pilling and fraying) |

| Strength-to-Weight Ratio | Superior | Good |

| Common Use Case | Heavy-duty gear, hiking packs | Daily use, school bags, promotional items |

Weather and Water Resistance Comparison

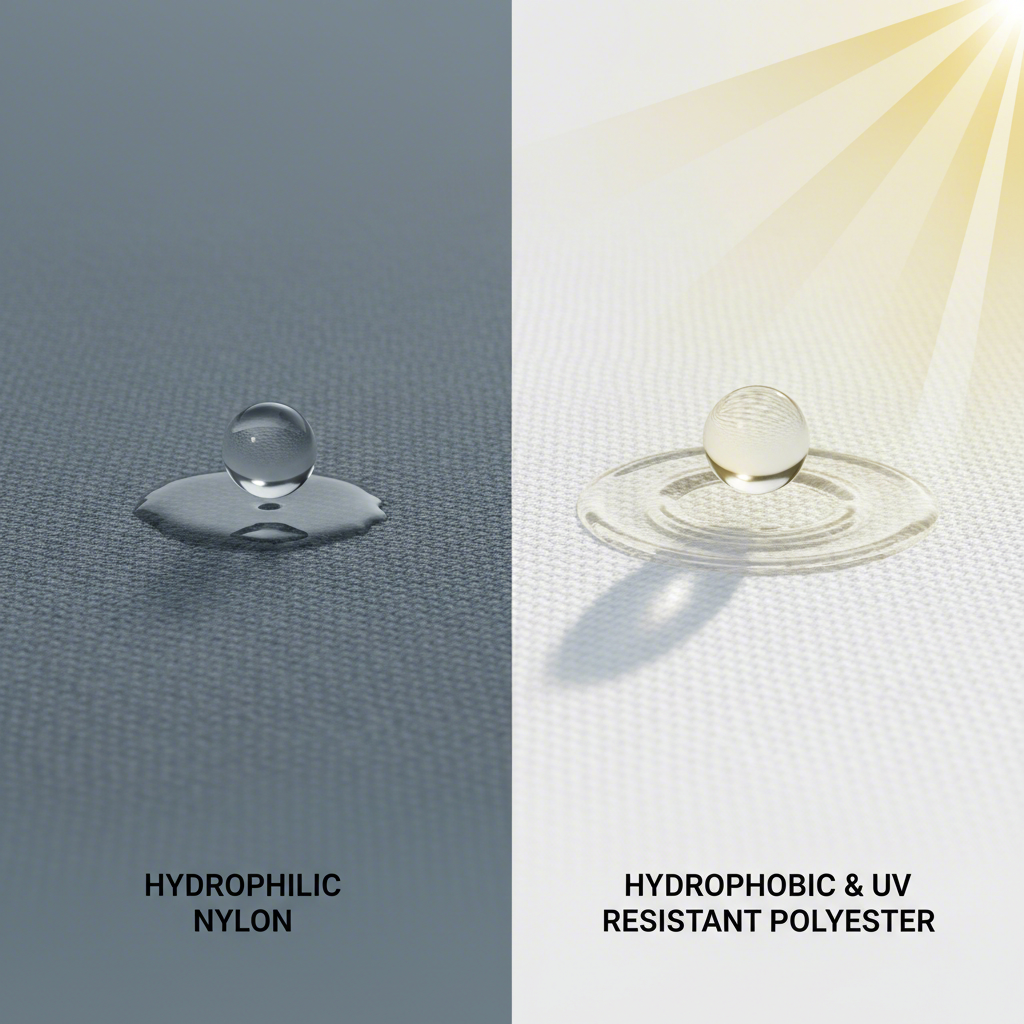

A drawstring bag's performance in different weather conditions is a critical factor, especially for outdoor activities or daily commutes. The way a fabric interacts with water and sunlight can significantly impact its longevity and the safety of its contents. Nylon and polyester have fundamentally different relationships with moisture and UV radiation, leading to distinct advantages and disadvantages in various environments.

Polyester is naturally hydrophobic, meaning it repels water. As explained by sources like Szoneier, this quality prevents the fabric from becoming saturated, allowing it to dry quickly and maintain its shape and weight when exposed to rain or humidity. Furthermore, polyester demonstrates excellent resistance to ultraviolet (UV) radiation. This means it is less likely to fade, degrade, or lose strength after prolonged sun exposure, making it an ideal choice for bags used frequently outdoors.

Nylon, in contrast, is hydrophilic, which means it absorbs water. When nylon gets wet, it can stretch and become heavier. To counteract this, most nylon bags are treated with a Durable Water Repellent (DWR) coating to make them highly water-resistant. While a DWR coating is effective at shedding water initially, the underlying fabric can still absorb moisture in prolonged downpours or highly humid climates. This absorption can cause the bag to expand slightly. Nylon is also more susceptible to degradation from sunlight over time compared to polyester.

When deciding between the two, consider your primary environment. For sunny climates or activities where the bag will be consistently exposed to the elements, polyester’s inherent water and UV resistance offers a clear advantage. For situations where you need maximum water repellency for short periods, such as a sudden rainstorm, a well-coated nylon bag will perform admirably.

Weather Performance at a Glance

Polyester Pros: Naturally water-repellent (hydrophobic), dries quickly, excellent UV resistance, resists stretching in humid conditions.

Polyester Cons: Water resistance can be compromised at seams without proper sealing.

Nylon Pros: Can be made highly water-resistant with a DWR coating, very strong even when wet.

Nylon Cons: Absorbs water (hydrophilic), can stretch when wet, degrades with prolonged UV exposure.

Aesthetics, Feel, and Weight

Beyond pure performance, the look and feel of a drawstring bag play a significant role in the user's choice. Factors like texture, sheen, weight, and how well the material holds color contribute to the overall aesthetic and user experience. Nylon and polyester offer different sensory and visual qualities that cater to different preferences, whether for a premium feel or for vibrant, long-lasting designs.

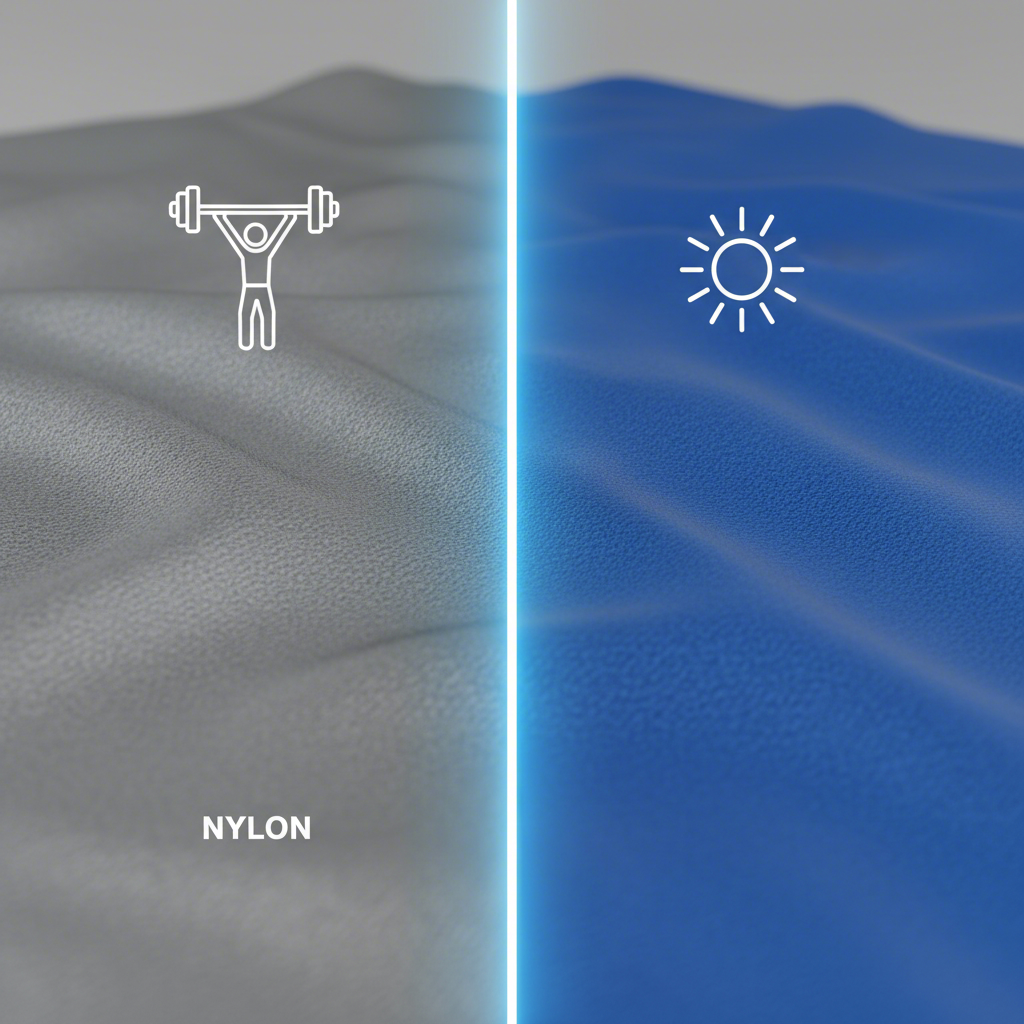

Nylon is often described as having a softer, smoother feel with a slight sheen or lustrous appearance, reminiscent of its original purpose as a silk substitute. This gives nylon bags a more premium and stylish look. While slightly heavier than polyester by volume, its superior strength-to-weight ratio means it can be engineered into very strong, lightweight fabrics. However, its tendency to absorb moisture can be a drawback for maintaining a pristine look in all conditions.

Polyester typically feels stiffer and has a more matte finish compared to nylon. It is an excellent canvas for dyes, holding color exceptionally well and resisting fading from UV exposure. This makes it the superior choice for brightly colored or custom-printed drawstring bags that need to retain their vibrancy. As noted by various sources, polyester is also more resistant to pilling, which helps it maintain a clean, new look for longer. While polyester is a lightweight material, it does not have the same strength-to-weight ratio as nylon.

Your choice in this category depends on what you value more. If a soft, premium feel and a sleek appearance are your priorities, nylon is an excellent option. If you want a bag with vibrant, lasting color, a cleaner appearance over time due to less pilling, and a more budget-friendly price point, polyester is the more practical choice.

Cost, Customization, and Environmental Impact

The final decision between nylon and polyester often comes down to practical considerations like price, suitability for customization, and sustainability. These factors are especially important for bulk purchases, such as for promotional events, sports teams, or retail. Both materials have distinct profiles in terms of manufacturing cost, ease of printing, and their environmental footprint.

Polyester is generally the more economical option. Its manufacturing process is less complex and costly than nylon's, making polyester drawstring bags a budget-friendly choice, particularly for large orders. This affordability, combined with its excellent color retention, makes polyester the go-to material for promotional bags. Its surface is highly receptive to various printing methods, including screen printing and heat transfer, ensuring that logos and designs appear crisp and vibrant. For wholesalers seeking custom promotional items, suppliers like Bincai Import and Export Co., LTD specialize in creating bespoke sewing products like custom drawstring bags, offering extensive options for adding logos and unique designs to bulk orders.

Nylon's more intricate production process makes it more expensive. This higher cost is justified by its superior strength and durability, positioning it as a premium material for high-performance gear where longevity is paramount. While nylon can be printed on, the process can be more challenging than with polyester.

From an environmental perspective, both materials are petroleum-based plastics, but their recycling stories differ. Polyester recycling is more established and efficient. Recycled polyester (rPET), often made from post-consumer plastic bottles, is widely available and helps reduce landfill waste and reliance on virgin resources. Nylon recycling is more energy-intensive and less common, though the use of recycled nylon from factory waste is growing.

| Factor | Nylon | Polyester |

|---|---|---|

| Cost | Higher | Lower (more budget-friendly) |

| Customization | Good | Excellent (holds color well, easy to print) |

| Environmental Impact | Harder to recycle, more energy-intensive | Easier to recycle (rPET is common) |

Frequently Asked Questions

1. Which is better, nylon or polyester thread?

Nylon thread is generally considered superior for applications requiring stretch and abrasion resistance. Its elasticity makes it an excellent choice for upholstery, footwear, and outdoor gear where materials experience heavy use and movement. Polyester thread, however, offers better UV resistance and is less affected by moisture, making it ideal for outdoor items like awnings or boat covers that are constantly exposed to the elements.

2. Is polyester or nylon better for gym bags?

Polyester is often the preferred choice for gym bags. Its hydrophobic properties mean it won't absorb sweat or moisture from damp clothes and towels, and it dries quickly, which helps prevent mildew and odors from developing. While nylon is stronger, polyester's moisture-wicking ability, affordability, and resistance to abrasion from being tossed around in lockers make it a more practical option for daily fitness use.

售前客服

售前客服