The Secrets to Non-Woven Polypropylene Bag Durability

TL;DR

Non-woven polypropylene bags offer exceptional durability due to their unique manufacturing process. Instead of weaving threads, polypropylene fibers are thermally bonded to create a strong, solid sheet of fabric. This construction makes the bags remarkably resistant to tearing, water, and daily wear, establishing them as a reliable and long-lasting alternative to single-use bags for shopping and promotional purposes.

What Makes Non-Woven Polypropylene So Durable?

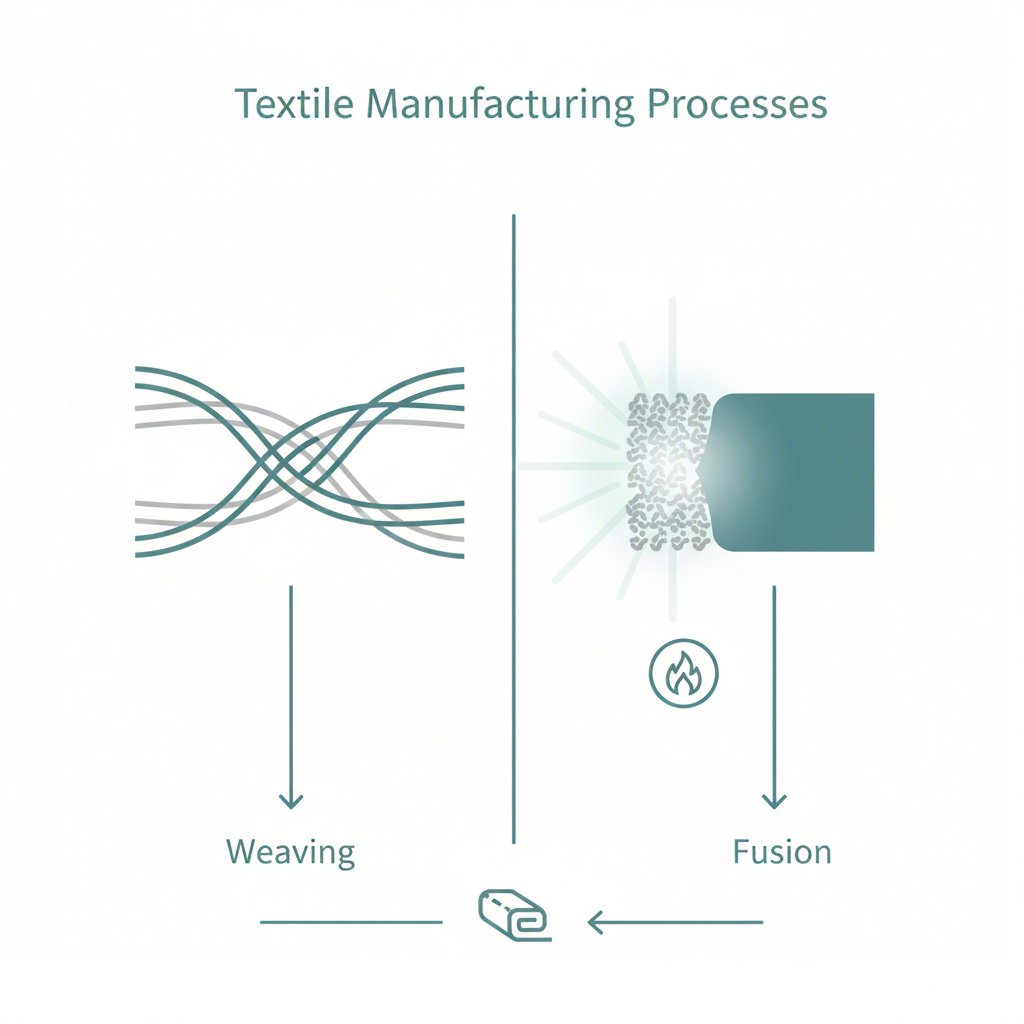

The secret to the impressive durability of non-woven polypropylene bags lies in how they are made. Unlike traditional fabrics that get their strength from an interlocking weave of threads, non-woven polypropylene is created through a process called spun-bonding. In this method, polypropylene plastic is melted and extruded into fine filaments, which are then laid down in a web and fused together using heat and pressure. The result is a solid, sheet-like material rather than a collection of individual threads.

This bonded structure is inherently strong because stress is distributed across the entire surface of the fabric, not concentrated on individual yarns that could pull apart or break. As explained by experts at Cotton Bag Co, this fusion of fibers creates a material with excellent stability and resistance to tearing. It fundamentally differs from woven polypropylene, where plastic threads are interlaced in a traditional crisscross pattern. While also strong, woven materials can be prone to separating if not laminated.

The manufacturing process also gives non-woven fabric a uniform texture that is both lightweight and resilient. This combination of strength and low weight makes it an ideal material for reusable bags designed to carry significant loads without adding unnecessary bulk. The solid nature of the fabric ensures it holds its shape and withstands the rigors of repeated use, from grocery shopping to daily commuting.

Key Characteristics of a Durable Non-Woven Bag

The durability of non-woven polypropylene bags isn't just a single feature but a combination of several beneficial properties. These characteristics work together to create a reliable, long-lasting product suitable for a wide range of applications. Understanding these specific traits helps clarify why they have become such a popular choice for eco-conscious consumers and businesses alike.

Strength and Tear Resistance: The bonded fibers create a material that strongly resists tearing and puncturing, allowing the bags to carry moderate to heavy loads without failure.

Water and Stain Resistance: Polypropylene naturally repels water, providing protection against light rain and spills. This quality, detailed in an article by Yanxin Bag, helps keep contents dry and makes the bags easy to wipe clean.

Lightweight and Portable: Despite their strength, these bags are incredibly lightweight and can be folded into a compact size, making them easy to store in a car, purse, or backpack.

Longevity and Reusability: Designed for repeated use, these bags can last for years with proper care, significantly reducing the need for single-use plastic bags and minimizing waste.

Customizability: The smooth surface of non-woven fabric is perfect for high-quality printing, making it a favorite for branding and promotional items.

These qualities make non-woven bags a practical and dependable choice for everyday use. Their resistance to wear ensures they maintain their integrity and appearance over time, offering excellent value. Because of these durable and highly customizable qualities, non-woven bags are a top choice for promotional items. For businesses looking for bespoke sewing products, suppliers like Bincai Import and Export Co., LTD specialize in adding logos and creating unique designs for bulk orders, leveraging over 15 years of experience.

Woven vs. Non-Woven: A Head-to-Head Durability Comparison

While both woven and non-woven polypropylene bags are celebrated for their strength, their durability profiles differ due to their distinct construction methods. Choosing between them often depends on the specific application and the type of stress the bag will endure. A direct comparison reveals the unique advantages each type offers.

Woven polypropylene is constructed from interlaced plastic threads, much like traditional textiles. This creates a flexible and often incredibly strong material, particularly in terms of tensile strength, making it a common choice for industrial sacks that hold heavy bulk items like grains or sand. However, as noted by 1 Bag at a Time, the individual strands can be slippery and may separate if the material is not laminated. In contrast, non-woven polypropylene's bonded fiber structure provides uniform strength in all directions and a smooth surface ideal for detailed printing, making it perfect for retail and promotional bags.

The following table breaks down the key differences in their durability characteristics:

| Feature | Woven Polypropylene | Non-Woven Polypropylene |

|---|---|---|

| Manufacturing Process | Plastic threads are woven together in a crisscross pattern. | Plastic fibers are spun and bonded together using heat and pressure. |

| Feel & Texture | Often has a visible checkerboard or basket-weave texture; can feel slightly coarse. | Smooth, fabric-like feel with a uniform, often dimpled texture. |

| Strength | Excellent tensile strength, ideal for very heavy loads. Can be stronger than non-woven, especially when coated. | Very good all-around strength; highly resistant to tearing and punctures. |

| Flexibility | Highly flexible and can conform to the shape of its contents. | Slightly more rigid but still flexible enough to be folded easily. |

| Common Uses | Heavy-duty sacks (sandbags, bulk food), durable shopping bags. | Reusable shopping bags, promotional totes, gift bags, dust covers. |

Ultimately, the choice between woven and non-woven comes down to priorities. As a hands-on comparison from Smart.DHgate concludes, woven bags often win for sheer toughness and holding heavy loads, making them a long-term workhorse. Non-woven bags, however, offer a superior balance of durability, affordability, and print quality, making them the versatile and popular choice for everyday consumer and promotional applications.

Frequently Asked Questions

1. Is non-woven polypropylene strong?

Yes, non-woven polypropylene is very strong. Its strength comes from the process of thermally bonding plastic fibers together into a solid sheet, which makes it highly resistant to tearing and capable of carrying heavy items. This makes it a much more durable option than paper or single-use plastic bags.

2. How long do polypropylene bags last?

With reasonable care, non-woven polypropylene bags can last for years. Their lifespan depends on factors like usage frequency and the weight they carry, but they are designed to be reused 50 to 100 times, making them a sustainable and long-lasting alternative to disposable bags.

3. What is the difference between polypropylene and woven polypropylene?

The primary difference is their construction. Woven polypropylene is made from plastic threads that are woven together, creating a material with a grid-like pattern similar to traditional fabric. Non-woven polypropylene, on the other hand, is made by fusing fibers together with heat, resulting in a uniform, sheet-like material without a woven pattern.

售前客服

售前客服